You may have noticed motorcycles driving around with what looks like fabric wrapped around the exhaust pipes from the engine to the muffler.

The thinking goes that the wrapping will insulate your legs and the rest of the bike against hot exhaust pipes so the heat goes out the back instead of burning your calves. With that comes hotter exhaust temperatures at your motor because it’s not dissipating in to the metal tubes as much, so it’s worth keeping in mind that it may be best to adapt your fuel systems to accommodate hotter exhaust temperatures.

Some people may say it improves engine performance and maybe there is a nominal gain, but that’s not what we’re looking at here.

Ultimately, if you’ve ever wondered why they’re wrapped or what they do the answer is: aesthetics, mostly.

Before we begin there are a few words of caution that need to be spoken: The higher exhaust gas temperatures may lead to exhaust header failure (Titanium may be more vulnerable) so you’ll need to accept the risk that comes along with wrapped headers.

This will illustrate how to re-wrap the exhaust headers on a nearly 20 year old Harley Davidson XL 1200, though the process will be similar for any bike.

Here’s the kit from Harley Davidson that contains everything necessary—enough wrap for both headers, clamps, and instructions. Note that it did not include the two-year old helper.

First—here are the required tools/materials:

- Motorcycle Exhaust wrap kit (the kit used was bought directly from the HD dealership)

- SAE ratchet set (metric for other makes) with extensions

- Torque wrench

- Leatherman multitool

- New exhaust header gaskets

- Measuring tape

- Garden hose

- Pliers

- Scissors

- Nitrile gloves

The wrap, itself, is a densely woven fiberglass material so be sure you handle with gloves!

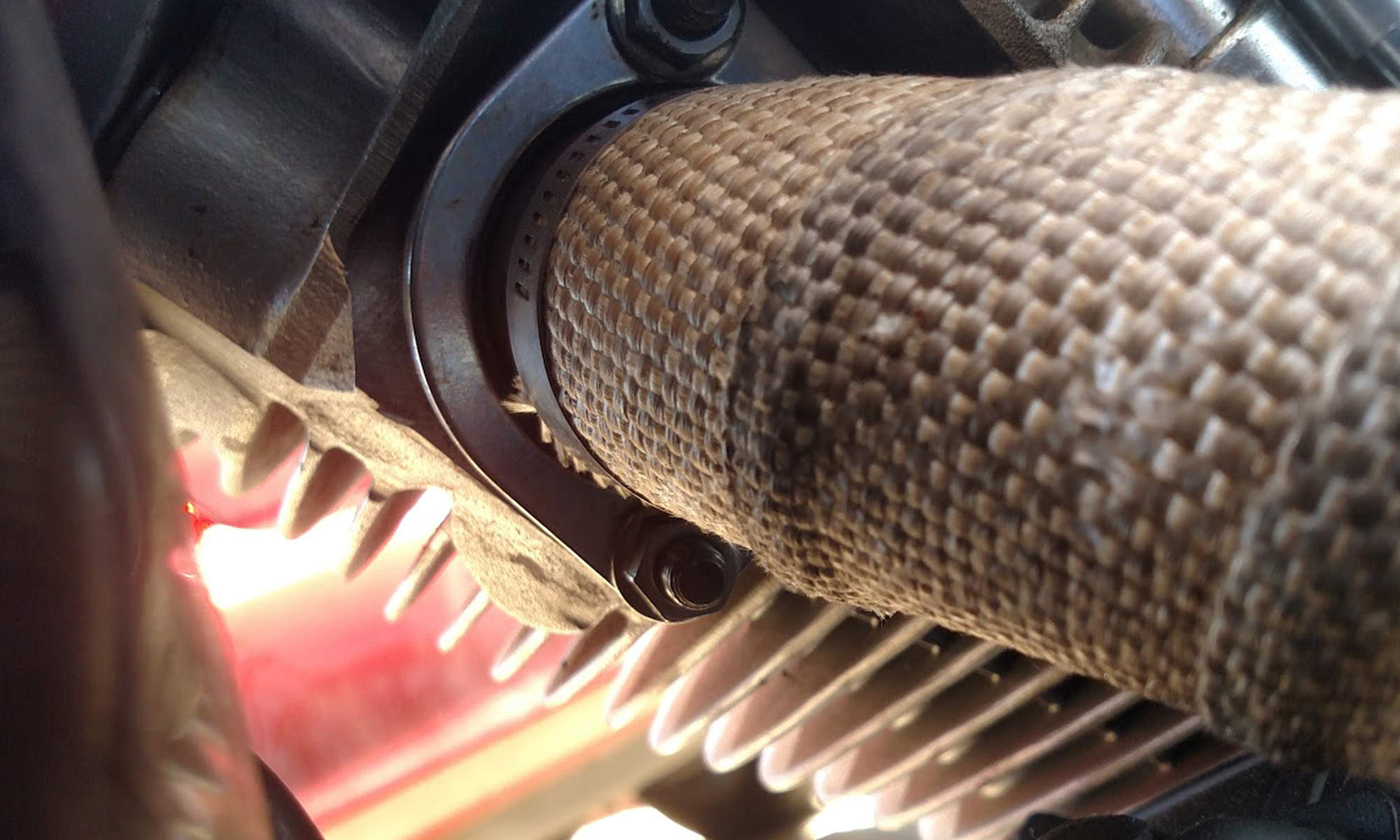

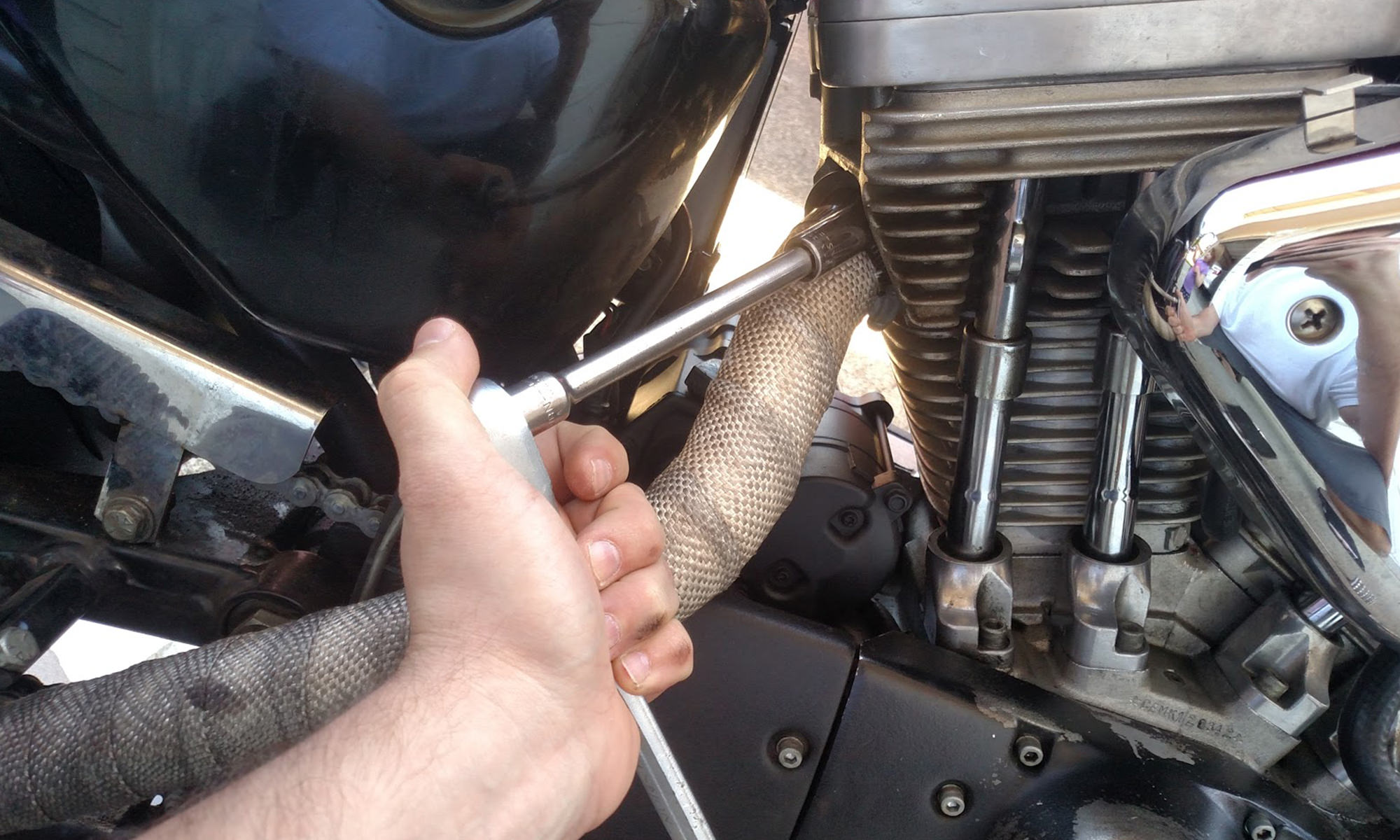

Begin by removing the exhaust headers from the motor using your ratchet and extensions. You’ll likely need a deep socket in order to accommodate the exhaust header studs. In this case it’s a 1/2" socket and you’ll need the extension in order to clear the tubes, themselves.

Next you’ll need to find the bolts that hold the exhaust to the frame of the bike in order to fully remove the exhaust. This bike uses a mount on the bottom of the mufflers.

Once you have the exhaust off the bike you’ll need to remove the mufflers from the headers. Over time, the extreme temperature swings and exhaust gasses an make for a difficult muffler removal, but once the clamp is removed that holds it to the tube you can wiggle it off with enough effort. It helped to have a pair of pliers handy for this step in order to hold the nut on the back while loosening the bolt but clearly another open wrench will work just fine if you want to take the time to find the right size.

At this point you’ll have a naked exhaust header. If the header, itself, is in poor condition then it will be a good idea to replace it, now, while everything is off of the bike. If they’ve been wrapped previously, as these have been, be sure to watch out for fatigue and rust. These are a good example of tubes that should have been replaced due to rust at the exit from the heads, though there were none on hand for this demonstration.

Be sure to clean up any debris or accumulated material now so you can re-wrap a clean pipe. You can scrape things off with a razor blade, if you need to.

Take the roll of exhaust wrap and get it wet; The instructions provided stated to get wet without soaking so this roll was sprayed with a garden hose, though soaking it shouldn’t be a problem, either. The key is that the wrap needs to be wet.

Measure from where the muffler joins the end where the exhaust mounts to the motor. If there are instructions with the wrap it may give you a conversion to estimate the length of the piece of wrap that you need.

One common mistake is to begin before sliding your exhaust flange back on the bike so be sure you do so. It’s fairly irritating to have wrapped your pipes only to find that your exhaust flange will not fit around the now-wider diameter of your pipes!

You can now begin wrapping your exhaust from the end that joins to the exhaust, starting just ahead of where the edge of the muffler will be. The reason you should start from this end is so the lip of each wrap faces backward and won’t accumulate road debris in the seams. It’s important to fold the frayed end of the wrap under just a couple of centimeters or so so it will be held under the wrap and wont’ fray in the future.

Being sure to hold it tightly, start wrapping around the pipe and overlap each wrap at least a centimeter or two (1/2"-3/4") until you get to the end where the exhaust flange sits. Tuck this frayed end under as well, and apply your clamp around it to secure it in place. This kit came with what amount to metal zip-ties but any metal hose clamp will work, as well. Once that end is secured go ahead and put a clamp on the muffler end, as well.

Repeat this process for the other tube.

With both tubes wrapped it’s time to re-assemble the exhaust system, so start by sliding the muffler and muffler clamp back over the end of the exhaust up to where it meets the beginning of your new wrap-job. Be sure to leave it loose because you’ll need to fit it back to the specific position where it meets the mounts on the bike.

Use new exhaust gaskets and fit the tubes to the heads and loosely secure in place with the nuts you took off. With the exhaust more-or-less in the correct position, start adjusting the muffler to mount to the bike. Once it’s lined up go ahead and put the bolts back in place so everything is good and tight. Note that your muffler clamp is still loose, at this point.

Make sure the exhaust headers are positioned correctly in relation to the head so they mate well—you may have to adjust it’s position with the muffler in order to do so. Once in the correct position, begin torquing the exhaust flange nuts down to the manufacturer’s specifications. At this time you may now tighten the collar that secures the muffler to the exhaust pipes.

Up to this point, the wrapped material has remained wet, if you recall. The reason you wet the wrap first is to make it more pliable to put on and will also snug and form to the pipes once your exhaust begins to heat up.

Go ahead and start the motorcycle and let it get up to operating temperature for about a half hour or so. There will be visible steam coming off the wrap that may look like smoke so don’t be alarmed! I don’t recommend breathing this vapor, either, as there may be chemicals off-gassing that you may want to avoid. Besides—it doesn’t smell good.

So there you have it! Your own DIY motorcycle exhaust kit! Go enjoy a good ride and let the wind do the rest! You’ve got a fancy wrap-job now so go riding around with your new look and worry less about the heat coming off of your exhaust pipes.